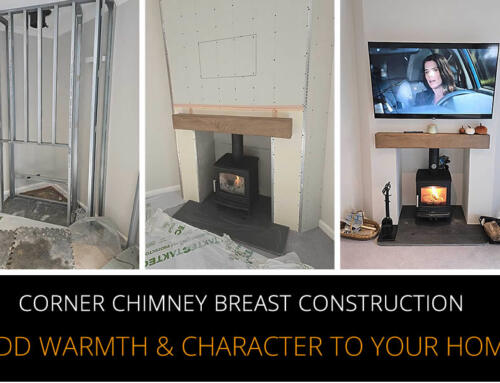

This project involved removing an existing stone surround in order to construct a false chimney breast.

On day one we generally install the entire twinwall chimney, construct the stud frame work and lay slate hearth ready for adding fireboard the following day.

Advice: Plan your false chimney breast construction in advance. Make sure there’s at least 150mm each side of the woodburner and I allow 1m height for top of recess. I make the width of the legs (or jams) of the chimney a minimum of 250mm, plus the 12mm width of the fireboard. Totaling 274mm each leg. You don’t want the legs to look too slim.

Note: The Twinwall chimney system is the black double skinned insulated flue chimney pipe which attaches to the vitreous pipe at the top of the woodburner and continues through he wall and up adjacent to the property and directed around the soffit, finishing high above the roof with a anti downdraft cowl.

Tip: We added strengthening supports within the structure of the false chimney breast in order to support a ceramic oak effect mantel and TV bracket, the central support was added encase one day the customer decides to remove the TV and instead wants to hang a mirror or picture. (Think ahead as very difficult to add post construction).

We use both U-Stud and C-Stud for the construction of the false chimney breast together with fireboarded for the bottom section following HETAS specifications. This allows for the correct distances to combustibles and provides a smooth surface for paining. The U-Stud is the horizontal stud work tracking, which the vertical C-Stud slots into. I use (2 x 2.4 meter lengths) for a standard fireplace and the C-Stud is the vertical studwork. I use about (12-14 x 2.4m) lengths depending on areas requiring reinforcement.

Tip: Check your ceiling height as 2.4m may not always be long enough!

We cut out the carpet before beding the hearth on sand and cement, while the fireboard will cover any gaps later.

Advice: Fireboard is fairly expensive, although benefits include plastering directly onto its smooth side. Other fire rated boards absorb moisture and need to be thoroughly PVA glued before plastering and have a rougher texture. I only use high quality fireboard, which can be cut similar to plasterboard by scoring with a knife. Other concreate boards are difficult to cut and may require an angle grinder with a stone disc.

Plasterboard can be then screwed to sides, front and top section of the false chimney breast ready for plastering. We use standard black dry wall screws that pierce the metal stud work for a firm fixing.

Once the false chimney breast is constructed it can be then plastered before the ceramic oak effect mantel is added.

Advice: Leave 4-5 days to dry before painting the plaster, initally with a watered down thin coat of paint.

If you want a false chimney breast constructed in the Somerset area, then call us on 07715 104420.

We would be happy to hear from you.